NANOSTRUCTURED METALS GROUP (NMG)

NMG is a research group based at UFMG – Universidade Federal de Minas Gerais – focused on processing, characterization and properties of light metallic alloys (Ti, Al, Mg) with structure features in the nanometric range.

The research in this field includes computer modeling of severe plastic deformation (SPD) techniques, processing of light alloys by Equal-Channel Angular Pressing (ECAP) and High-Pressure Torsion (HPT) and development of superplasticity in magnesium and aluminum. SPD is used to refine the grain structure of metallic materials and improve mechanical properties.

In recent years, the focus of the research has been the understanding of corrosion behavior of nanostructured magnesium alloys, the use of HPT to produce nanostructured metal matrix composites and assessing the potential of nanostructured magnesium (and magnesium based composites) as a biodegradable material.

The group is composed by researchers and graduate and undergraduate students from different fields of Engineering.

PEOPLE:

- Roberto B. Figueiredo – Group leader

- Debora R. Lopes – Pos-doc

- Mariana Medeiros – Ph.D. Candidate

- Leonardo Reis – Ph.D. Candidate

- Amanda Carvalho – Ph.D. Candidate

- Andressa Cristina – Undergrad

- Isabella Meireles – Undergrad

RESEARCH

Processing by Severe Plastic Deformation

Processing by severe plastic deformation refines the grain structure and increases the strength of metallic materials. The most common techniques are equal-channel angular pressing (ECAP) and high-pressure torsion (HPT). Our group uses finite element modeling to study the evolution of strain and temperature and occurrence of plastic instabilities in these processes.

Metal Matrix Composites

Our group studies different routes to mix different materials in Mg based composites. The second phase aims to improve the mechanical properties and biological response of the composite compared to the pure metallic alloy.

Corrosion

Unintended degradation of metallic materials by corrosion is a major concern for industrial and biological applications. Our group aims to understand the corrosion behavior of nanostructured aluminum and magnesium alloys. We also aim to reduce the degradation rate of magnesium in biological environment.

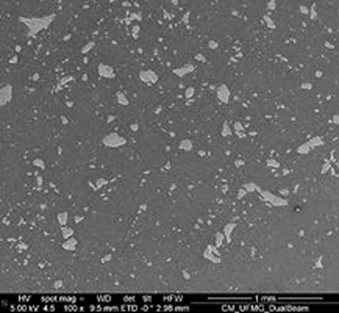

Deformation Mechanism and Structure Characterization

The structure of the materials dictate their properties. Our research group aims to improve the understanding of the relationship between structure and deformation mechanism of nanostructured light alloys.

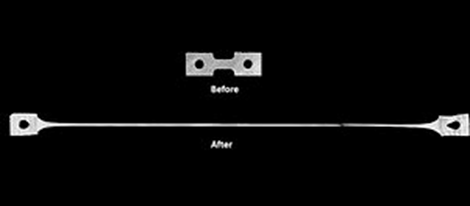

Creep and Superplasticity

The creep behavior of ultrafine grained and nanostructured alloys are strongly influenced by grain boundaries. Many alloys exhibit superplastic behavior with elongations over 400% in tension at high temperatures. Our group carries out research on the determination of creep mechanisms, development of superplasticity and evolution of cavities and defects during high temperature deformation of Al and Mg based alloys.

RESEARCH PROJECTS (ongoing)

- Bioactive and biodegradable magnesium matrix composites (Debora Lopes)

- Effect of grain refinement on corrosion behavior of magnesium (Mariana Medeiros)

- Scaling up severe plastic deformation (Leonardo Reis)

- Deformation mechanisms in nanostructured alloys (Amanda Carvalho)

ONLINE VIDEOS

OPEN ACCESS PAPERS

An Overview of the Effect of Grain Size on Mechanical Properties of Magnesium and Its Alloys

Amanda P. Carvalho and Roberto B. Figueiredo

https://www.jstage.jst.go.jp/article/matertrans/64/7/64_MT-MF2022005/_pdf/-char/en

An Overview on the Effect of Severe Plastic Deformation on the Performance of Magnesium for Biomedical Applications

Mariana P. Medeiros,Debora R. Lopes, Megumi Kawasaki, Terence G. Langdon and Roberto B. Figueiredo

https://www.mdpi.com/1996-1944/16/6/2401

Using high pressure torsion to process magnesium alloys for biological applications

Mariana P. Medeiros, Amanda P. Carvalho, Augusta Isaac, Conrado R.M. Afonso, Miloš Janeček, Peter Minárik, Mayerling Martinez Celis, Roberto B. Figueiredo

https://www.sciencedirect.com/science/article/pii/S2238785422020166

Deformation mechanisms in ultrafine-grained metals with an emphasis on the Hall–Petch relationship and strain rate sensitivity

Roberto B. Figueiredo, Terence G. Langdon

https://www.sciencedirect.com/science/article/pii/S2238785421005718